High turnover of flex workers – high training cost

Challenges that many companies working with blue collar workers nowadays face are becoming increasingly relevant, not only in terms of direct financial cost, but also in terms of time and planning – productivity. Resources are limited, and their proper use is of key importance if we wish to do our daily operations successfully and with as less worrying and energy loss as possible. If you are running a production, transportation, logistics company, or are in any similar industry that employs blue collar permanent staff and flex workers, chances are you are very much aware of the issues discussed in the following paragraphs.

Maybe you currently do not have the need to hire additional staff, but you might in the future because i.e. you expect your business to grow, you have seasonality peaks and will need hire externally due to higher workload, etc. You are already now thinking about training these new people and allocating resources accordingly. You spend significant amount of your daily working time on planning and arranging business processes to be all set for onboarding of your new personnel. Once everything is arranged, new talent is in and everything seems to be running smoothly, an (un)surprising event strikes again – people are leaving. Numbers and reasons may vary, and those will not be the focus of this article, but the fact remains – you lose a certain number of the personnel that you needed, have planned for the workload in the coming period and which you have already partly trained.

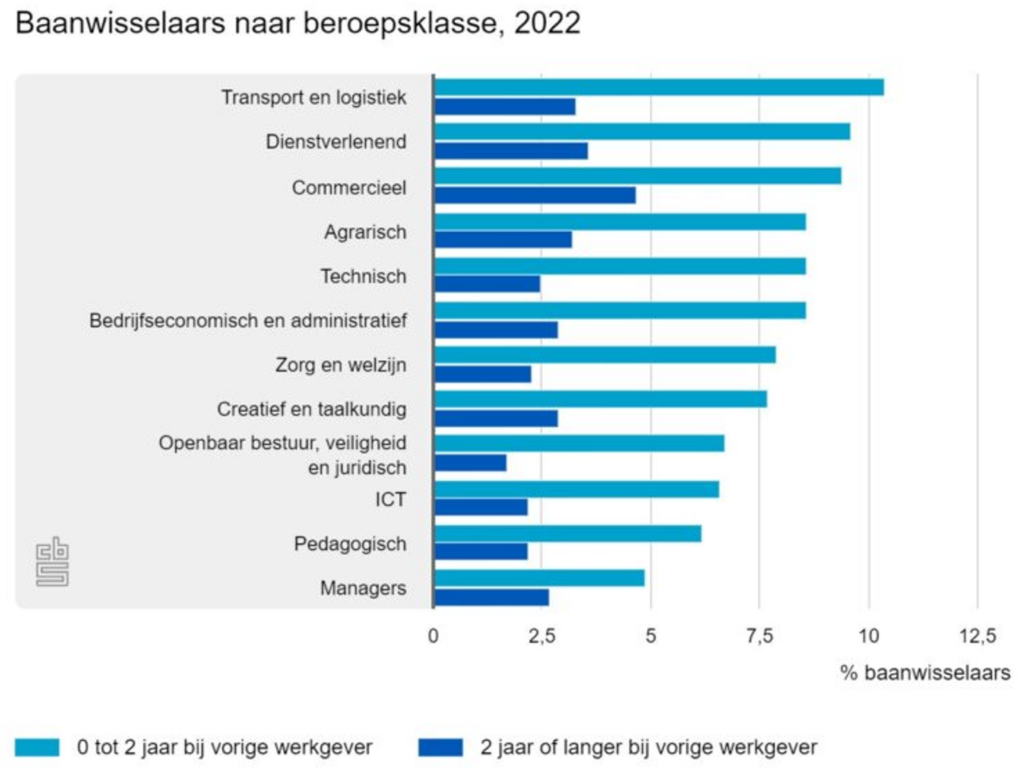

Research by CBS shows that in- and outflow of personnel in the Netherlands occurs the most in transport and logistics sector. In 2022, 4.7% of total employees changed jobs per quarter. 60% of employees remained at their employer for 3 months before switching to another one. Most of these people are flex workers. The graph shows the percentages in correlation to occupational sectors:

Source: CBS

Logistics sector champion job hopper • Warehouse Total

Impact of employee outflow on productivity and costs

One logistics company from south of the Netherlands has estimated that the cost of training of one newcomer is around 5.000,- EUR monthly. This figure can be extrapolated to other similar sized organizations in the region. For example, if the organization with the total of 50 FTEs has 5% outflow rate per month, that leaves them with loosing 2,5 FTS’s which need to be trained, monthly. Taking in the training cost estimation of 5.000 EUR of 1 FTE, we get the figure of 12.500,- EUR monthly training costs due to outflow only. Now, who would not be pleased with the fact that this amount of money can be saved on employee turnover!

But as mentioned in the beginning, there is more to it than just financial aspect. Just how much was team productivity impacted? How many hours were spent unproductive? When the most skilled team member is taken off of their regular activity (usually it is a team leader) to train the newcomer, one can imagine just how negatively the productivity of labour, and hence quality and output turn out. The following table demonstrates the figures in the example of order picking activity at one company from the Netherlands. Considering hourly costs of trainer; trainee, their time input, hourly wages, productivity fluctuation during weeks, the total cost after 4-week training period sums up to 3.630 EUR.

| Training process | Hourly cost of trainer (EUR) | Hourly cost of newcomer (EUR) | Time of trainer needed for training | Time of trainee needed for training | Cost of a trainer (EUR) | Cost of a trainee (EUR) | Total cost (EUR) | Week | Productivity (%) |

| Order picking | 30 | 30 | 40 | 40 | 1200 | 1200 | 2400 | 1 | |

| Order picking | 30 | 30 | 10 | 12 | 300 | 360 | 660 | 2 | 70% productivity |

| Order picking | 30 | 30 | 5 | 8 | 150 | 240 | 390 | 3 | 80% productivity |

| Order picking | 30 | 30 | 2 | 4 | 60 | 120 | 180 | 4 | 90% productivity |

Source: PPS

It’s nice to imagine what would be the output of our labour only if the occupation had stayed 100%, just as we idealized. But there is no need to idealize or fantasize. There is no need to try the best to prevent employee outflow or be dependent on instability. Close all excel sheets with calculations about how much money was wasted last quarter due to frequent turnover.

Curious to find out about the possible solutions? Download the white paper. It is important to fill in all the blocks while downloading the whitepaper, otherwise link will not work! If you do not wish to share all the data, we understand and respect your will, in that case write something else simply to fill in the block.

Solutions - High turnover of flex workers: high training costVerzend link naar: |

leave your comment